How the Focus RS Drifts

For the third generation Focus RS Ford set out to create something special and this required the best transmission setup. GKN Driveline were tasked to develop a new version of its Twinster torque vectoring all-wheel drive (AWD) system which would be basis of the cars unrivalled handling capabilities. GKN used an innovative combination of new gearing ratios and control algorithms over-speed the rear wheels, helping Ford to create a car with unprecedented dynamics, feel and handling.

Why did Ford work with GKN I hear you ask? The company is the only one with the hardware, software and vehicle integration expertise for a project of this kind.

How it works

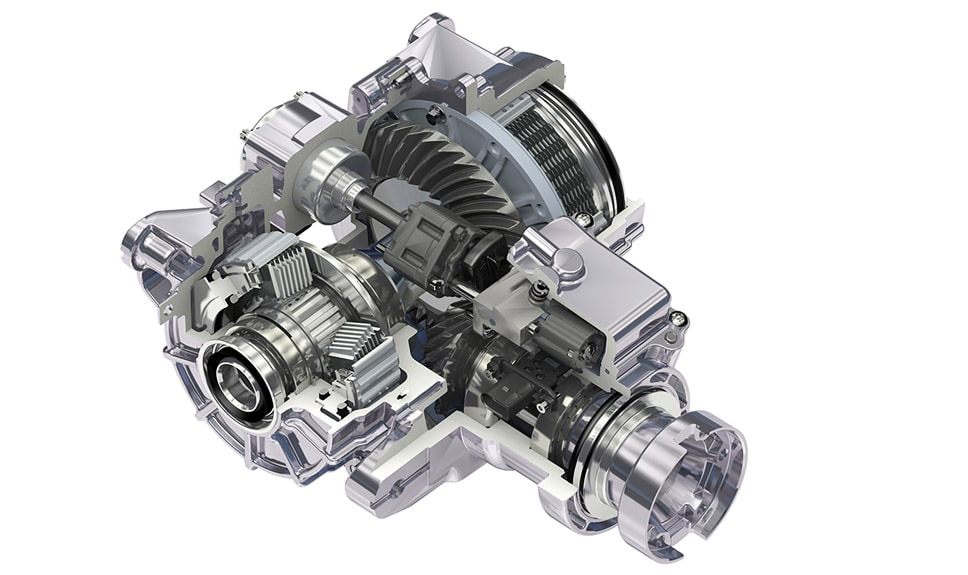

A GKN AWD system drives the car with a Final Drive Unit (FDU) that uses a Twinster twin clutch system. The Twinster can apply torque to one or both rear wheels independently, enabling the vehicle’s dynamic torque vectoring functions across its entire speed range.

The version in the Focus RS uses new gearing ratios so that it delivers more torque to the rear wheels. When AWD is engaged, the rear wheels drive faster than the front, fundamentally changing the way the car feels and handles.

The vehicle turns into curves more sharply, responding more immediately to the driver’s inputs. In Ford’s “drift mode”, the AWD system delivers even more torque to the rear axle, delivering enough torque to the rear wheels for the Ford Focus RS to achieve a controlled “drift” through corners.

What it takes

To deliver torque vectoring systems of this calibre requires engineers who understand vehicle dynamics and with Ford awarded GKN the programme with just 18 months to go before launch. In that time GKN engineers designed and integrated both the Torque Vectoring FDU, as well as the Power Transfer Unit (PTU) and CV joint sideshafts into the base front wheel drive platform.

Due to the complexity of this entire system everything had to work in harmony during the R&D. GKN’s in-house software and calibration teams and Ford’s vehicle dynamics engineers worked together on new control algorithms for the torque vectoring system to give the driveline four different driving modes.